Metal Fixed Valve Trays: Stationary High-Capacity Solutions for Fouling-Prone Fractionation Systems

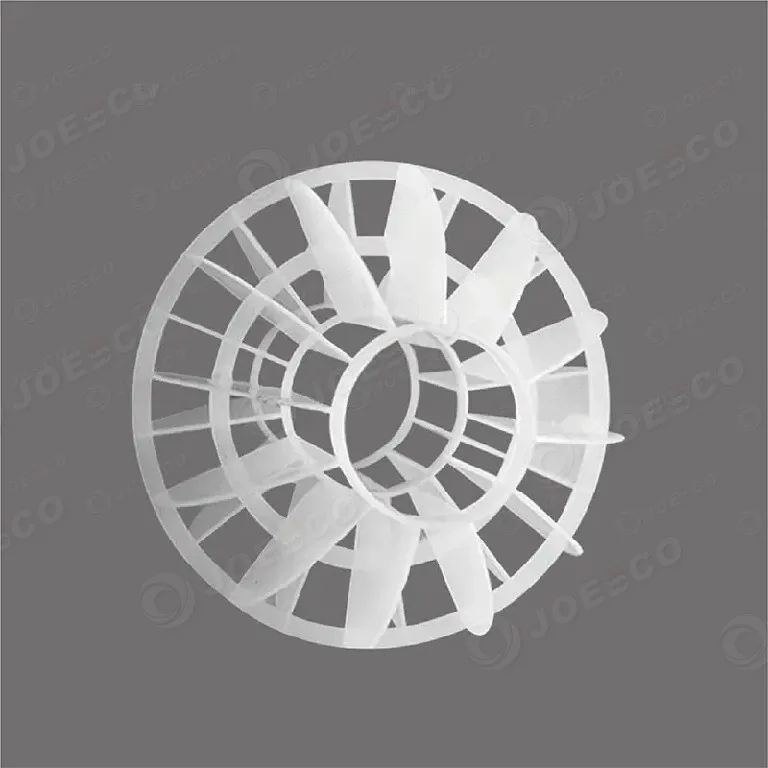

Engineered for Reliability Metal Fixed Valve Trays feature permanently open valve units that deliver sieve-tray simplicity with enhanced vapor-liquid contact. By eliminating moving parts, they prevent wear/sticking while achieving 20-30% higher capacity and 6:1 turndown ratios versus sieve trays – ideal for fouling services like FCC main fractionators and PVC