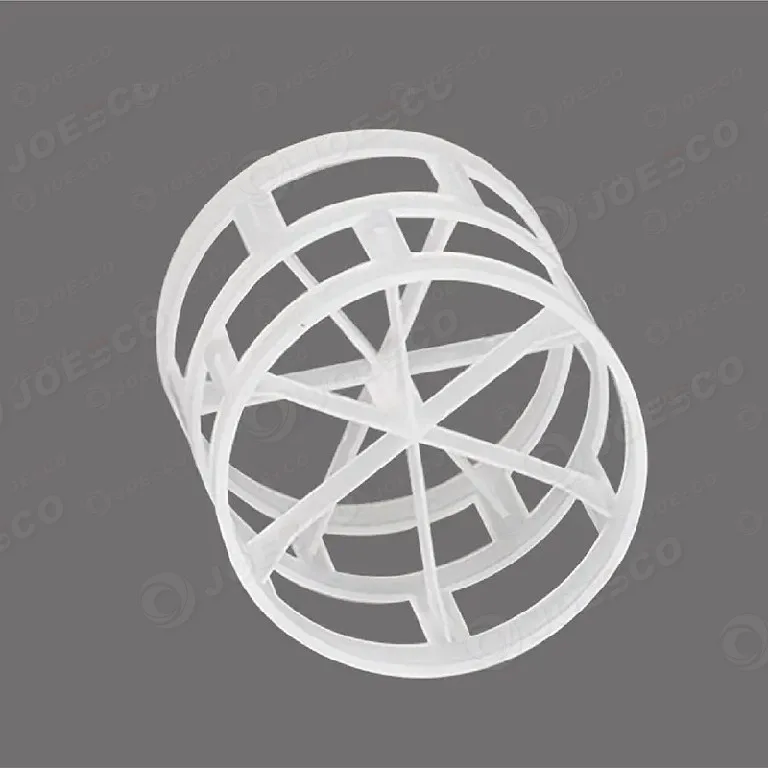

Triangular Spiral Packing – Precision Fenske Design for High-Resolution Separation

Triangular Spiral Packing – Where Geometry Meets Efficiency When you need to push the limits of separation efficiency in laboratory or specialized industrial applications, triangular spiral packing delivers a distinct advantage. As a member of the Fenske spiral family, this packing replaces conventional circular coils with a triangular wire winding pattern. This simple geometric shift creates more defined flow paths and increased surface contact—giving you sharper separations, even when dealing with challenging mixtures like isotopes. We appreciate designs that use smart geometry to solve practical problems. The triangular shape provides more interaction points per spiral turn compared to standard springs, leading to better vapor-liquid distribution. While it does come with a slightly higher pressure drop, the gain in separation performance is often well worth the trade-off in high-value applications