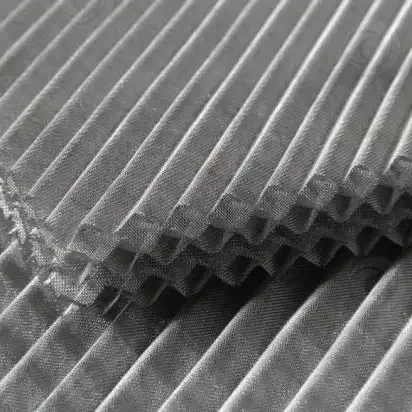

Metal Wire Gauze Corrugated Structured Packing is engineered from woven metal wires (stainless steel, Monel, copper) into corrugated sheets. Renowned for its low pressure drop and exceptional separation efficiency, it is the industry’s preferred choice for precision distillation, vacuum distillation, and high-purity applications.

Key Features & Benefits

- Ultra-High Efficiency: Optimized geometry maximizes theoretical stages (>8 plates/m for Y-type).

- Minimal Pressure Drop: Corrugated channels reduce energy consumption.

- Material Versatility: Available in SS304/316, Monel, copper for corrosion resistance.

- Precision Performance: Ideal for demanding separations requiring high purity.

- Customizable Designs: 30° (X-type) for low ∆P, 45° (Y-type) for superior mass transfer.

Specifications Table: Metal Wire Gauze Structured Packing

| Model | Specific Area (m²/m³) | Bulk Density (kg/m³) | Voidage (%) | Pressure Drop (Pa/m) | Theoretical Plates (m⁻¹) |

|---|---|---|---|---|---|

| 250X | 250 | 125 | 97 | 100 – 400 | 2.5 – 3 |

| 500X | 500 | 250 | 95 | ≤400 | 4 – 5 |

| 700Y | 700 | 280 | 87 | 600 – 700 | 8 – 10 |

Design Variations

- X-Type (30° Corrugation): Lower pressure drop, ideal for vacuum systems.

- Y-Type (45° Corrugation): Enhanced mass transfer, optimal for high-purity distillation.

Applications

Deploy Metal Wire Gauze Packing in critical processes requiring high efficiency and reliability:

- ⚡ Vacuum & Atmospheric Crude Oil Fractionators

- ⚙️ FCC Main Fractionators

- 🌫️ TEG (Triethylene Glycol) Dehydration Contactors

- 🧪 Precision Chemical Distillation

- 🌡️ Pharmaceutical & Specialty Chemical Purification

Why Choose Our Metal Wire Gauze Packing?

Opt for structured packing when processes demand:

- High theoretical stage counts

- Low liquid-rate absorption/stripping

- Wide operational flexibility

- Tower retrofits for capacity/efficiency upgrades

Our corrosion-resistant wire gauze packing offers unmatched versatility for new builds and column retrofits, with custom geometries tailored to your process.