Engineered Fluid Management

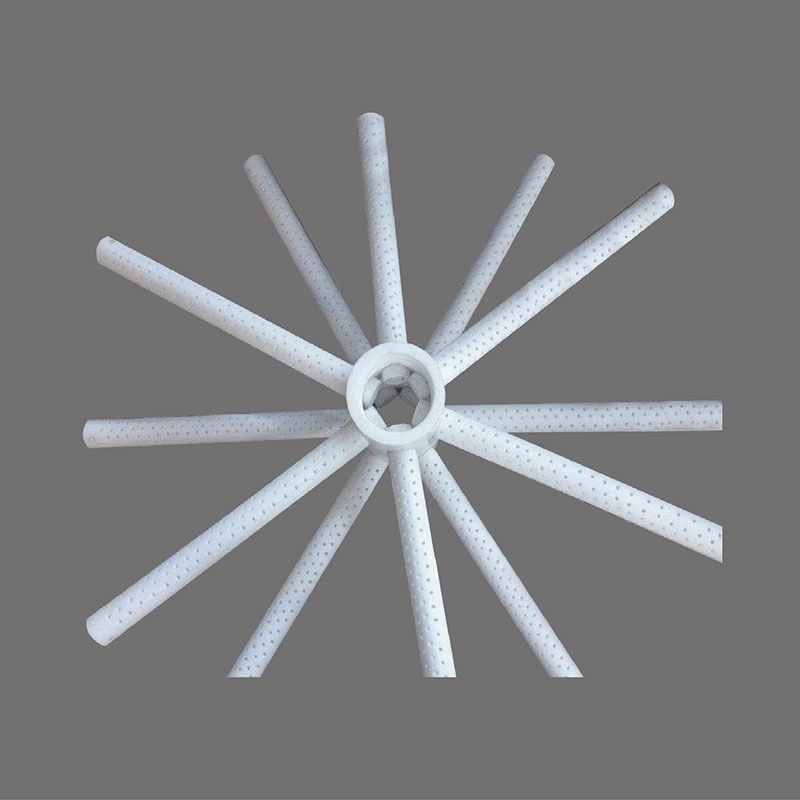

Pipe Liquid Distributors deliver uniform fluid distribution/collection through modular tube-and-header systems. Featuring flange/thread connections and optional porous liners, they maintain ±3% flow deviation across 1-100 bar systems. PTFE construction enables ≤260°C operation with 99% chemical resistance in acid/solvent services.

Core Technology

| Feature | Technical Advantage |

|---|---|

| Modular Tube Array | Achieves CV ≤0.05 flow uniformity in distribution/collection modes |

| PTFE Construction | Withstands conc. HNO₃/HCl/NaOH ≤260°C (FDA/USP Class VI compliant) |

| Pressure Resilience | Certified for 100 bar @ 150°C (ASME B31.3) |

| Anti-Fouling Design | Wedge-shaped gaps enable 95% backwash efficiency in slurry services |

| Zero Dead Zones | 2D flow geometry prevents particle accumulation (cGMP compliant) |

(Configuration options: radial/axial headers, multi-tiered arrays)

Industrial Applications

► High-Purity Chemical Processing

- Pharma API crystallization feed systems

- Semiconductor etch bath distribution

- Ultrapure water distribution networks

► Aggressive Media Handling

- HF alkylation unit quench systems

- Titanium sponge reduction reactors

- Electrolytic cell electrolyte management

► Pressure-Driven Operations

- SCF extraction (CO₂/HFCs)

- Reverse osmosis pretreatment

- Catalyst bed feed distribution