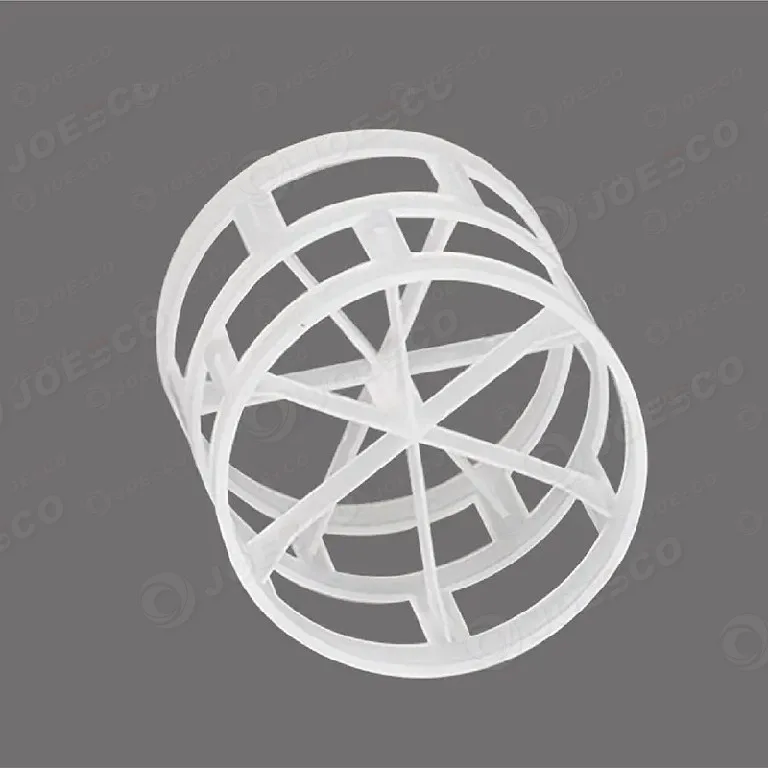

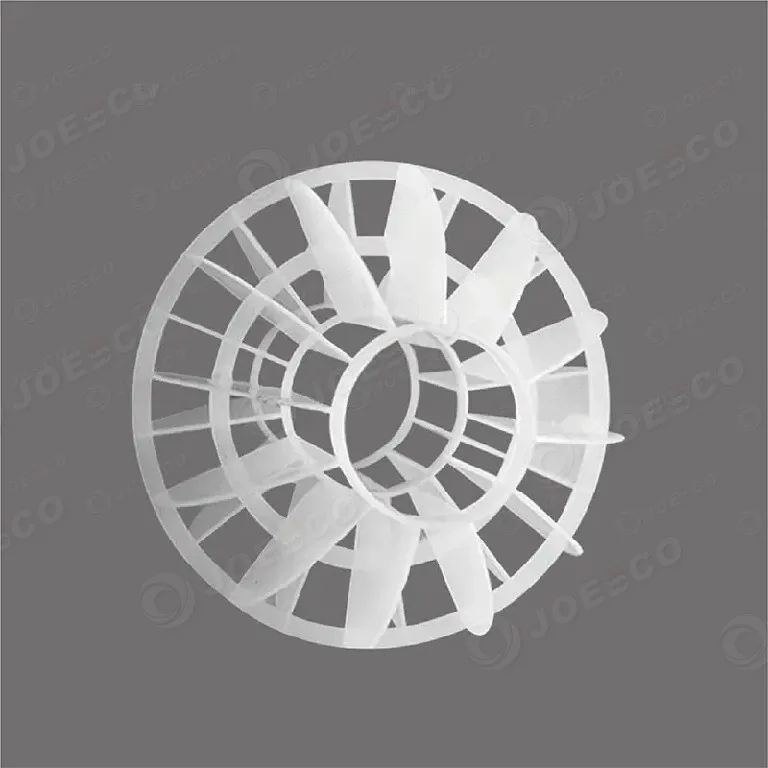

Plastic Tellerette Rings – High-Capacity, Low-Pressure Drop Packing for Gas Scrubbing

Plastic Tellerette Rings – Reliable Performance in Demanding Environments When you need a packing that can handle high gas loads without clogging or excessive pressure drop, plastic Tellerette rings deliver consistent results. Their unique spiral-like design creates an open structure that promotes uniform gas-liquid contact while resisting fouling—making them a go-to choice for scrubbing, purification, and chemical processing duties. We appreciate designs that balance performance with practicality. Tellerette rings work by guiding fluids through a continuous, open pathway. This reduces flow resistance and prevents solids buildup, which means less downtime and more stable operation in tough applications like exhaust gas treatment or alkali chloride processes. Clear Specifications – Easy Sizing Model Dimensions (mm) Surface Area (m²/m³) Void Fraction (%) S 47×19 185 88 M 73×27.5 127 89 L 95×37 94 90 Where They Perform Best Gas scrubbers and chemical purification towers Alkali-chloride and coal gas industry applications Environmental air treatment systems Processes with dirty or fouling-prone streams Why Choose Plastic Tellerette Rings? Low Pressure Drop: Open structure cuts energy costs Fouling Resistant: Handles dirty gases without clogging Temperature Resistant: Works from 60°C to 150°C Easy to Install: Lightweight and simple to load If you’re looking for a packing that combines hydraulic capacity with fouling resistance, Tellerette rings offer a proven solution for demanding gas-liquid contact applications.