Metal Dual Flow Trays: Downcomer-Free Fouling-Resistant Solutions for Severe Polymerization & Slurry Services

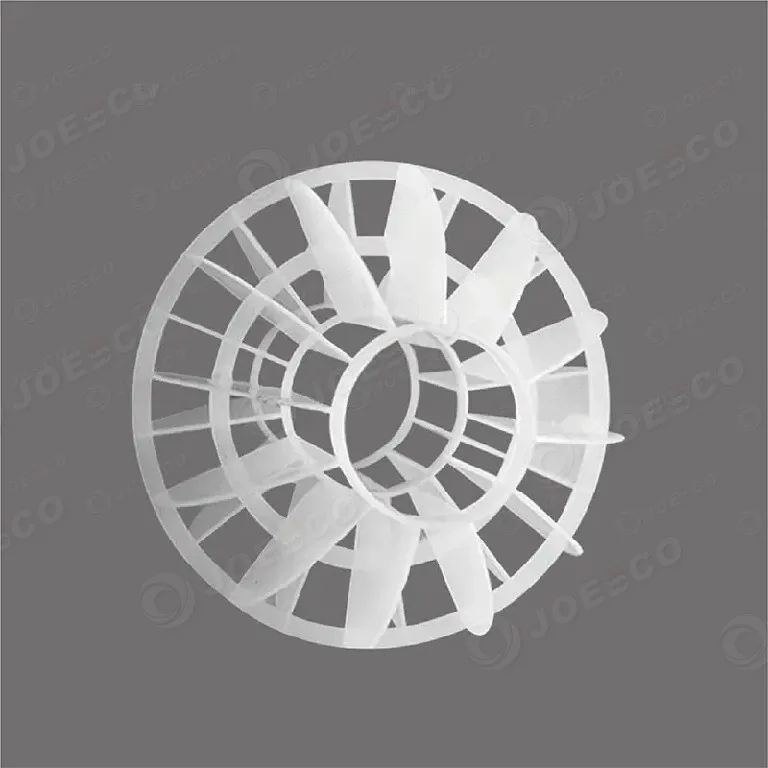

Engineered for Extreme Fouling Metal Dual Flow Trays eliminate downcomers entirely, utilizing large perforations (Ø12-25mm) that enable simultaneous vapor/liquid passage. This self-scouring action delivers unmatched fouling resistance in polymerizing/slurry services like PVC stripping towers and refinery vacuum sections – where conventional trays would fail within months. Core Technical Specifications Parameter