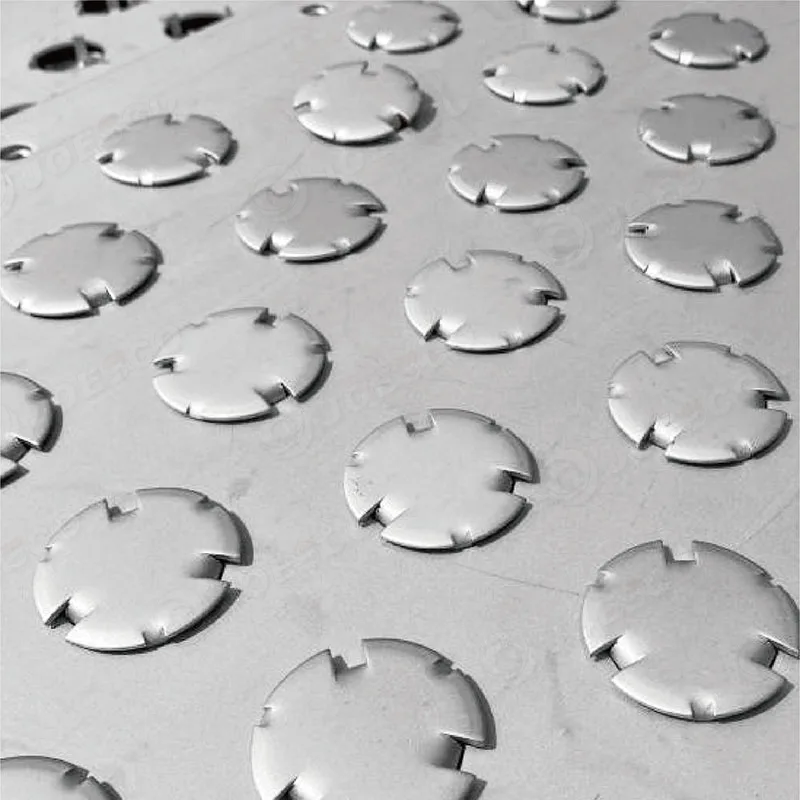

Dynamic Flow Control

F1 Metal Conventional Valve Trays feature circular valves with twist-locked legs that automatically modulate openings based on gas velocity. This self-adjusting design maintains optimal vapor-liquid contact across 4:1 turndown ratios while preventing valve detachment – delivering reliable efficiency in FCC main fractionators, NGL columns, and gas sweetening units.

Core Mechanism

| Component | Function |

|---|---|

| Twist-Lock Legs | Secures valves while permitting vertical travel (no detachment risk) |

| Peripheral Spacers | Maintains minimum opening at low gas loads (prevents sticking/sealing) |

| Variable Openings | Auto-adjusts from 20-100% to match vapor flow (F-factor 0.8–3.5 Pa⁰·⁵) |

(Valve movement range: 8-25mm based on gas velocity)

Performance Advantages

- Adaptive Efficiency: Maintains ≤15% Murphree efficiency variance across load ranges

- Entrainment Control: Reduces droplet carryover 40% vs. sieve trays at high vapor rates

- Fouling Resistance: Leg/spacer design prevents debris accumulation in coking services

- Pressure Flexibility: Validated from vacuum (0.1 bara) to high-pressure (20 barg) operations

- Proven Reliability: >50,000 installations in refineries since 1960s

Industrial Applications

► Refinery Critical Units

- FCC main fractionators

- Delayed coker fractionation

- Naphtha stabilizers

► Gas Processing

- NGL/LPG recovery columns

- Amine regenerator towers

- Glycol dehydration contactors

► Petrochemical

- Ethylene cracker quench towers

- BTX extraction columns

- Olefins concentration stages