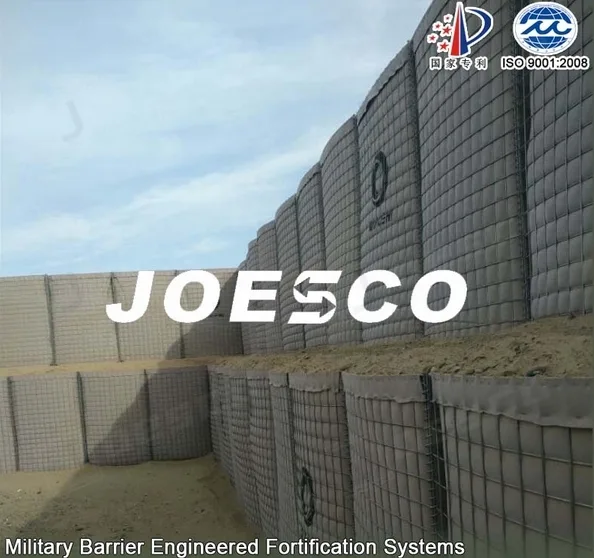

Hesco Barrier anping factory

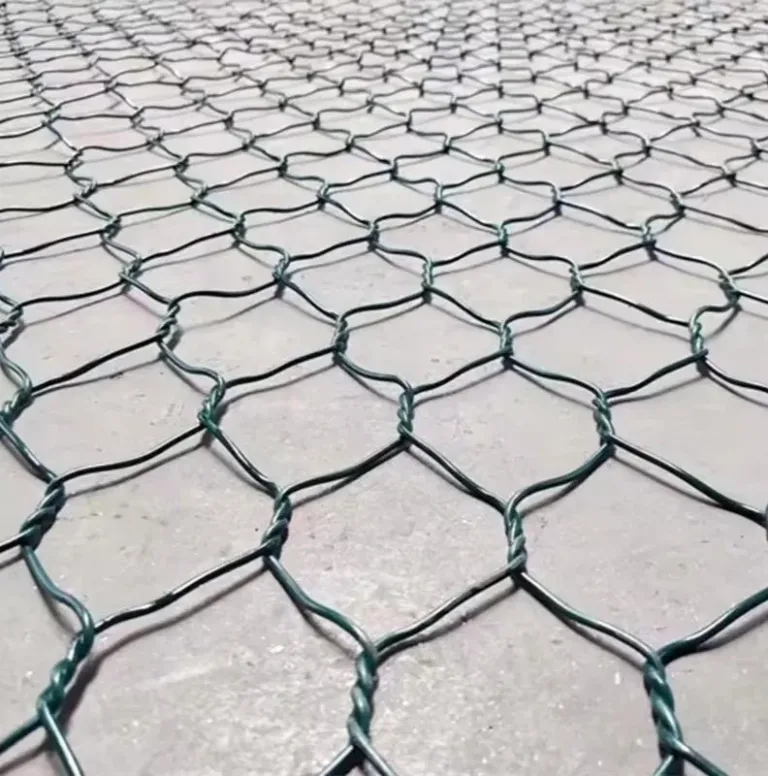

Hesco Barrier is also called the flood control wall is modern metal mesh used for flood control and military fortifications.Is made up of a foldable wire containers and heavy of geotextile and become,it is used as a temporary or permanent barriers or in the fortress to block or small attack.