Water and wastewater treatment CO₂, SO₂, HCl, and HF gas absorption/stripping Drinking water purification Odor control and chlorine scrubbing

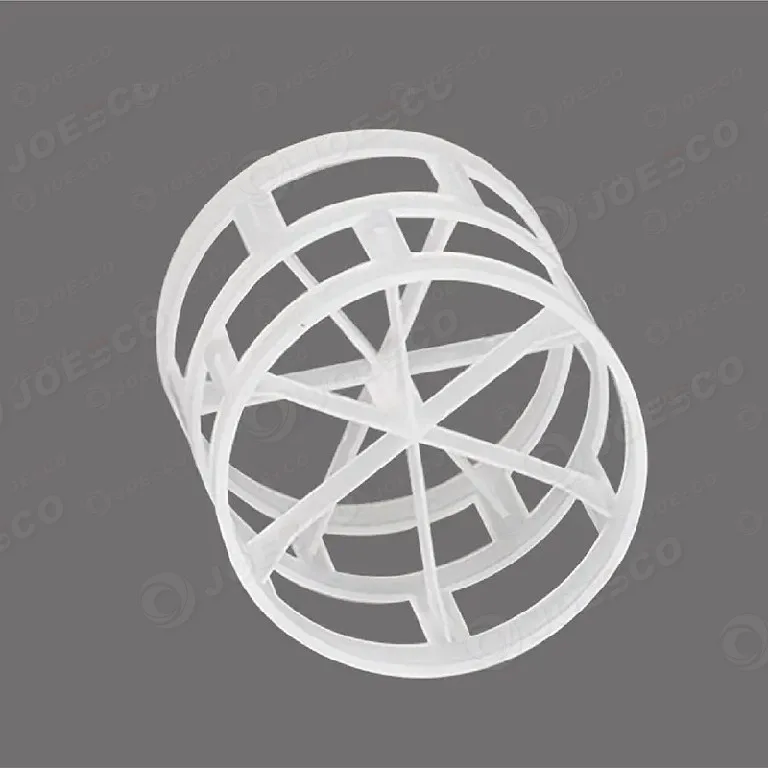

Good Distribution: Uniform flow leads to consistent performance Corrosion Resistant: Handles many chemicals without degradation Cost-Effective: Lower price point than metal, with solid performance Fouling Resistant: Open design reduces clogging risk